Leveling up throughput and reproducibility at VIB’s Core Facilities with Opentrons

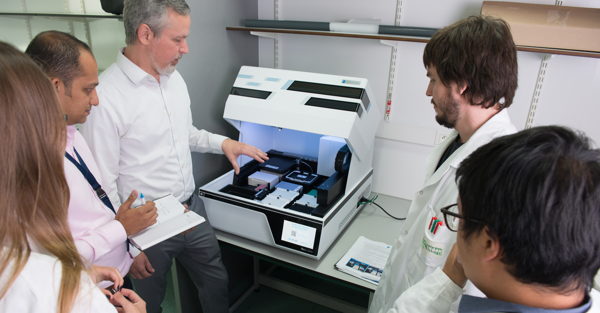

For many organizations, automation is the holy grail of process optimization. At VIB Technologies, the potential of robotics has become more apparent over the years as well. To save time on labor-intensive and repetitive processes such as sample preparation, VIB’s Core Facilities have recently started to rely on Opentrons. The implementation of these multipurpose robots has enabled the Cores to make strides in time efficiency and data reproducibility, with decreased waiting times for end users as a result.

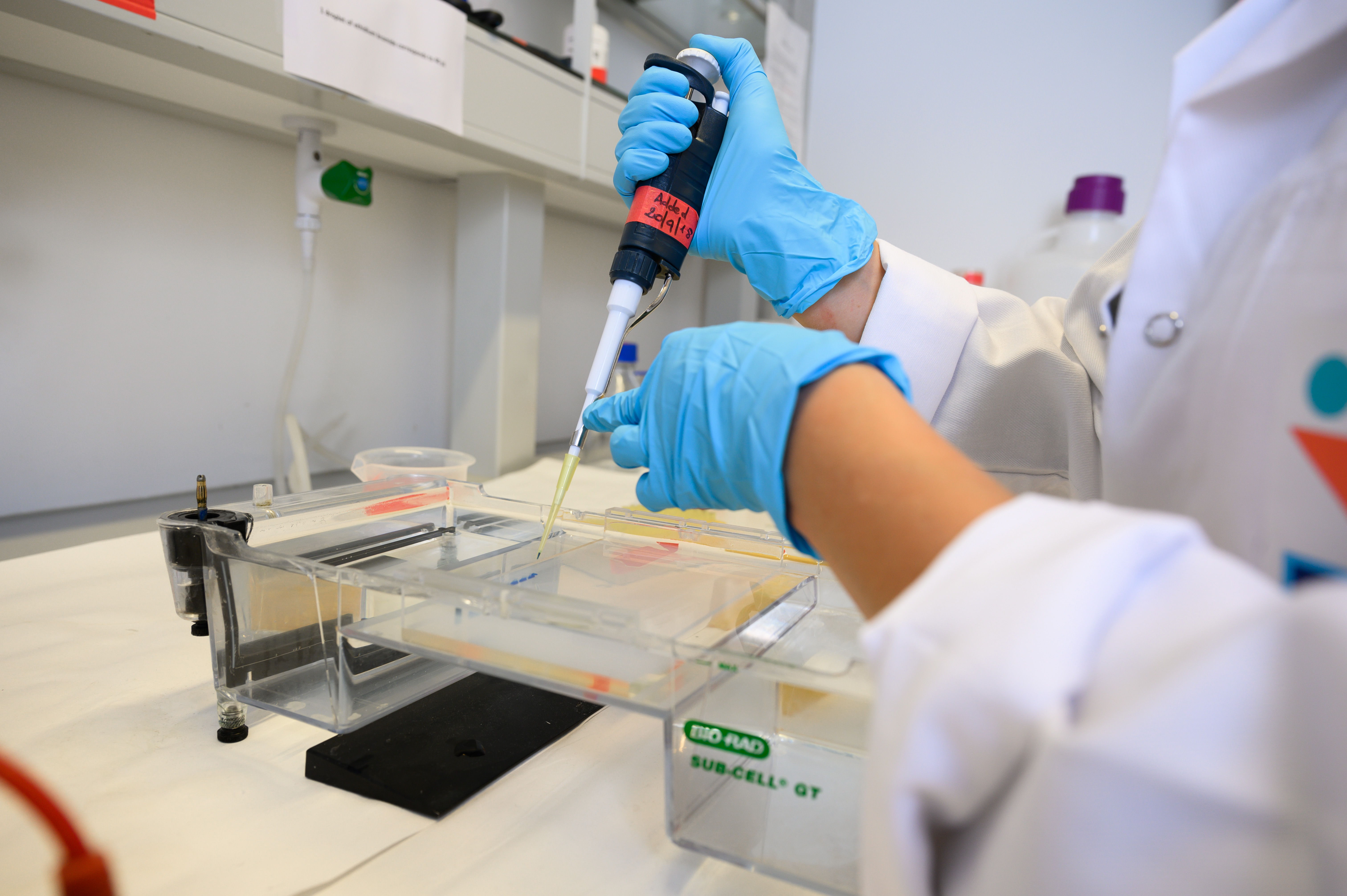

Even though innovations in DNA sequencing, mass spectrometry or other frequently used omics technologies have resulted in more accurate and qualitative output over the years, one thing that has not changed all that much is preparing samples before they are analyzed.

It is a challenge shared by most Cores all around the world: sample preparation requires intensive manual labor and often results in bottlenecks. The process requires repetitive, manual manipulations and takes up quite a bit of time. The tools lab technicians have at their disposal have seen some nifty upgrades over the years (for instance well plates with larger capacities and multichannel pipettes), but the scalability of such processes has not evolved dramatically with waiting times for end-users remaining quite high.

At VIB Technologies, this is a daily reality too. The ever-increasing inflow of service requests has resulted in some Core Facilities actively considering the integration of robotics to automate routine sample prep procedures and free up valuable time. With success: VIB’s Nucleomics Core fully automated an entire library preparation pipeline, dramatically scaling up the throughput of samples and drastically cutting down on waiting times.

“Over the past few years, we became more and more conscious of what automation could offer us in terms of service flexibility,” explains Stefaan Derveaux, Head of VIB’s Nucleomics Core, “Thanks to the integration of customizable Opentrons units in some of our library preparation pipelines, we exponentially increased our volume throughput. Where we previously could only process one well plate with about 24 samples at a time, we now automated that same pipeline to simultaneously process 96 samples, and even more. Since its implementation in October 2021, more than 10.000 samples have been processed successfully using this automated pipeline. Needless to say, this has been quite the improvement for both our end users and our lab technicians.”

Where Stefaan’s lab previously spent an estimated 90% of time on sample preparation, automating such workflows has brought that number down significantly. Because of that, lab technicians can spend more time on workflows that are not suitable for automation and require a more human touch.

Robotic DIY

The successful test-run of Opentrons in the workflows of the Nucleomics Core led to the integration of robotics in other Cores as well. Both at VIB’s Proteomics and Metabolomics Cores, OpenTrons are now making their entry and improving workflows.

“Admittedly, we were a bit wary when we first started playing around with the Opentrons systems. The devices are relatively cheap compared to more specialized robotics and they were marketed as multipurpose machines that could easily be implemented in a multitude of workflows. To our surprise, it turned out that they are indeed incredibly versatile,” explains Simon Devos, VIB Proteomics Core Manager, “The Opentrons systems are very customizable, meaning that with the right script, they can be implemented in a broad range of workflows. They can be equipped with different modules that enable the automation of different steps in proteomics sample preparation. Thanks to that, we can now fully cut out manual interventions and leave it to the machines. All you need is a bit of a do-it-yourself mentality and then the possibilities are plenty.”

.jpg)

Because precision is a crucial factor in sample preparation, there is little room for human errors. In combination with an increasing demand for Core Facility services, the challenge to keep reproducibility at the required level and guarantee the quality of data output is very real. Luckily, an added benefit of working with fully programmable robotics is that human errors can be kept to an absolute minimum.

Geert Goeminne, Head of VIB’s Metabolomics Core in Ghent explains: “There used to be a time when the end-users had to prepare samples themselves, back when we were still working with a liquid-liquid extraction method. As a consequence, it happened regularly that samples were not prepared correctly and that the work had to be done all over again. Today, we see a trend where samples are becoming smaller and smaller, meaning that a correct preparation is becoming even more difficult. This is where robotics are a tremendous added value: once they are correctly programmed, they are not prone to mistakes and the standardization of each sample can be guaranteed.”

A sentiment seconded by Simon: “The sheer volume of samples our lab technicians need to handle on a daily basis is astonishing. What’s more, proteomics projects usually have waiting times of 4 to 6 weeks. When we get a sample, that’s the amount of time it usually takes to finish the report and send it back to the end-user. For some projects, that’s already quite long because researchers usually need to move quicker than that. In other words, the pressure to deliver on time is very real. By automating the lengthier parts of these processes, we can get deliver data much quicker.”

Upscaling and… downscaling?

While upscaling the volume of samples that can be processed at a time has clear benefits in terms of waiting times and standardization, there are other potential advantages to the introduction of robotics as well. According to Stefaan Derveaux, the introduction of Opentrons has also led to the downscaling of reaction volumes. An important side-effect as it results in lower prices for end-users.

“We work with commercial kits for sample preparation,” adds Stefaan, “Previously, when this work was still done by lab technicians, we were able to process about 96 samples with 1 kit. With our automated pipeline, we can make much more efficient use of these kits and cut reaction volumes in half. That means we’re downscaling on the reagents we use and that’s very interesting from a cost-efficiency point of view.”

For researchers, the cost of using cutting-edge technology such as flow cytometry or DNA sequencing is a tricky business. Thanks to Core Facilities, complex and high-tech machines in these fields have become much more accessible.

“Accessibility is more than just being able to use these machines. The cost of using our services remains an important factor there as well. If we can bring that down by being smart about how we use resources such as reaction volumes, I would call that a positive – and even sustainable – step forward ,” concludes Stefaan.

Looking ahead

Following on the positive experiences with automation in VIB’s Core Facilities, an automation working group evaluates and identifies further opportunities in integrating robotics in different Cores. Even though the applications might differ from facility to facility, the added value is largely identical: saving time, assuring quality of data output and alleviating bottlenecks in sample prep.

Geert Van Minnebruggen, VIB Technology Director: “We are continuously looking to improve our workflows to ensure our end users are serviced better while maintaining high levels of quality. The Opentrons story is just one way of how we are creating a tightly and efficiently knit ecosystem of technology expertise and services. The automation workgroup will make sure that integrating robotics can continue to contribute to this endeavor.”

Want to know more about VIB’s Core Facilities? Get to know them better here.

Interested in joining the team? Have a look at our job listings.